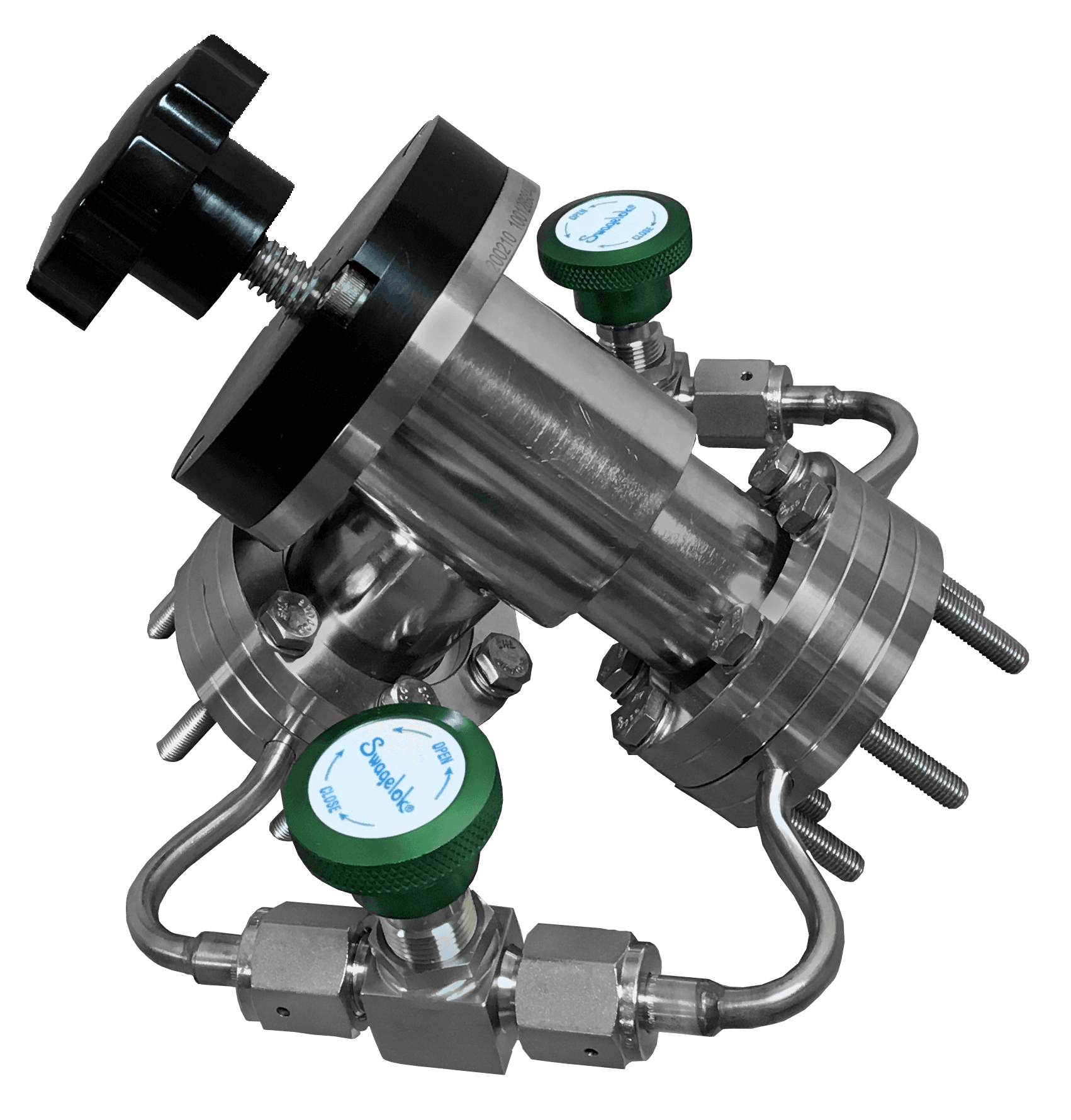

High Conductance Valve with Pressure Reduction Bypass(es)

The High Conductance Valve, built from 304 stainless steel, offers one or two pressure reduction bypasses, each featuring a Swagelok bypass valve and flow control orifice. It ensures an effective seal with an Elastomer poppet and offers versatile connections for different chamber pressures. The unit comes with all required hardware and is leak-tested prior to assembly.

Specifications

| Specification | Value |

|---|---|

Material | 304 Stainless Steel |

Weight | 6 lbs. |

Max Temperature Rating | Bakeable to 150 °C |

High Conductance Valve | Elastomer O-ring seal |

Flange Dimensions | 2-3/4 in. OD ConFlat Flange, 1.5 in. Tube OD |

Swagelok Valve Connection Size | ¼ inch VCR with flow control orifice sized to the customer’s request |

Downloads

| File Name | Document Type | Date | File Size | |

|---|---|---|---|---|

XT Series High Conductance Valve with Pressure Reduction Bypass(es) Datasheet | PDF | 2025-03-26 | 283 KB |